Industrial Cardboard Box Shredder

MOQ : 1 Piece

Industrial Cardboard Box Shredder Specification

- Thickness

- Up to 20 mm

- Frequency

- 50 Hz

- Application

- Cardboard Box Recycling

- Material

- Mild Steel

- Motor Power

- 7.5 HP

- Noise Level

- Less than 70 dB

- Sheet Capacity

- Up to 30 sheets

- Size

- 2200 x 900 x 1200 mm

- Automatic Grade

- Automatic

- Processing Type

- Shredding

- Color

- Gray

- Capacity

- 250-500 kg/hr

- Control System

- PLC Controlled

- Weight

- 850 kg

- Voltage

- 380V

- Number of Blades

- 12

- Maintenance

- Low Maintenance Required

- Installation Type

- Floor Mounted

- Energy Consumption

- 2.5 kWh

- Safety Feature

- Overload Protection

- Shred Size

- 40 mm strips

- Feed Opening

- 400 mm

- Blade Material

- High-quality Alloy Steel

- Dust Extraction

- Integrated Dust Extraction System

- Usage Mode

- Continuous Duty

- Drive Type

- Electric Motor

- Cutting Type

- Cross-Cut Shredding

Industrial Cardboard Box Shredder Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Good Quality Export Worthy Packaging

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Industrial Cardboard Box Shredder

Waste disposal is no longer an issue when you have the Industrial cardboard box Shredder. This paper shredder can simplify your desk with its handy desk-top design for office use. With the Industrial cardboard box Shredder, you are able to quickly and efficiently dispose of papers that are no longer needed by providing a simple way to destroy sensitive documents before they take up space in the trash or recycling bin.Efficient Cardboard Recycling Solution

This industrial shredder streamlines cardboard box recycling by efficiently reducing bulk material into manageable 40 mm strips. Built with an advanced cross-cut mechanism and a high-powered 7.5 HP electric motor, it ensures continuous duty operation for optimal throughput and energy efficiency. Its integrated dust extraction maintains a cleaner workspace.

Advanced Safety and Control Features

Safety and reliability are paramount. The shredder is equipped with overload protection to prevent motor strain, and the user-friendly PLC system offers precise automated control. The low-maintenance design means operators can focus on productivity rather than repairs or adjustments.

FAQ's of Industrial Cardboard Box Shredder:

Q: How does the integrated dust extraction system benefit users of the cardboard box shredder?

A: The integrated dust extraction system helps maintain a clean and healthy work environment by capturing dust particles generated during shredding. This reduces airborne contaminants and keeps the workspace tidy, ensuring smoother operation and lower maintenance needs.Q: What materials and sheet capacities can this shredder handle?

A: Designed for industrial use, the shredder can process mild steel cardboard boxes with thicknesses up to 20 mm and handle up to 30 sheets at a time, making it suitable for high-volume recycling operations.Q: When should the overload protection feature be expected to engage?

A: The overload protection activates automatically if the shredder senses excessive load or a jam, safeguarding the motor and components from damage. This ensures consistent performance and extends the machine's lifespan.Q: Where can this industrial shredder be installed?

A: The shredder is floor-mounted, designed for installation in industrial settings like recycling plants, warehouses, or large manufacturing facilities across India. Its compact design (2200 x 900 x 1200 mm) allows for flexible placement in busy environments.Q: What process does the shredder use to cut cardboard, and what is the resulting shred size?

A: Utilizing a cross-cutting blade assembly of 12 high-quality alloy steel blades, the shredder slices cardboard boxes down to uniform 40 mm strips, ensuring material is suitable for recycling and efficient disposal.Q: How is the shredding process controlled and regulated?

A: The shredder uses a PLC (Programmable Logic Controller) system, which automates and manages operational parameters for safety, efficiency, and precision, allowing for continuous, hands-off operation.Q: What are the primary benefits of using this industrial cardboard box shredder for businesses?

A: Businesses benefit from rapid, continuous shredding (up to 500 kg/hr), enhanced workplace safety, reduced labor efforts, low energy consumption (2.5 kWh), and minimal maintenance. These features collectively boost productivity and support sustainable recycling practices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Shredder Category

Industrial Metal Shredder

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutter Type : X cut

Noise Level : Medium db

Power(W) : Direct Watt (w)

Safety System : Yes

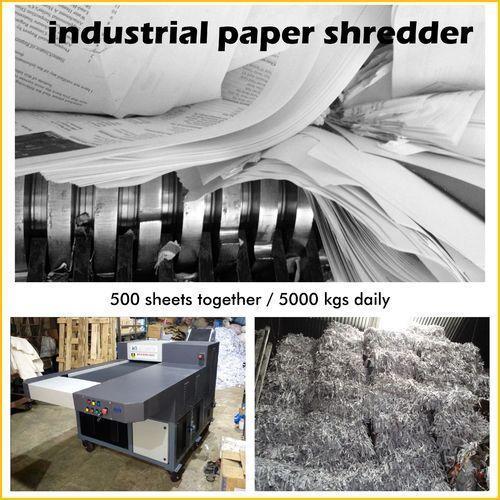

Industrial Paper Shredders

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Cutter Type : X cut

Noise Level : Medium db

Power(W) : Direct

Safety System : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free